The Harness Plug Handler

It takes a pretty careful coxswain to make sure the harness plug in the boat never flops into the water as the boat is set in the water, or lifted back out. Those are dangerous moments for the exposed metal inside the harness plug, when it can swing close to the water and is not yet , or no longer, plugged safely in to the cox box--but of course, those are the same moments when most coxswains are busy doing at least three of the following: making sure the fin doesn't get knocked off, checking that that the bow won't hit the boat on the far end of the dock, seeing if the 2 man is actually ready to go "one foot up and out," trying to remember the first seven drills of the warm-up, keeping the six water bottles she is carrying from falling, and wondering if he remembered to charge the cox-box in the first place.

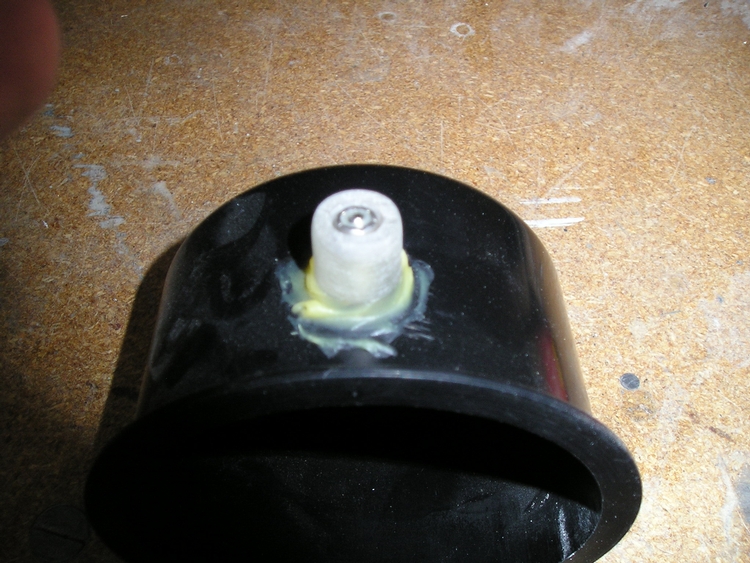

The Master Rigger's solution: keep that plug, well, plugged. He mounts a short bit of 5/8" diameter acrylic rod on the side of the "cox-box cup" in the boat. When the coxswain unplugs the cox-box, she just "plugs" it onto this holder, where it can stay--both water-tight and dry-in-the-first-place--until after the boat is back in the water for the next row and it is time to plug the box in again.

Sound like a better fix than having to trouble-shoot iffy harnesses or replace corroded plugs? Then here is the how-to from the man himself:

"The knobs on the cox box cups are just 3/4" lengths of 5/8" diameter acrylic rod. I attach them to the side of the cup with plastic welder and a machine screw and nut. The flat head of the machine screw is countersunk inside the cup and the nut fits in a counterbore in the outer end of the knob."

You can probably skip some of the finer craftsman bits--the countersinking and the welding--that make the original a real piece of well-hacked work, and still come up with something equally effective with a screw or some strong glue to mount the knob. You could even attach the knob itself to the hull or bulkhead, so long as the harness wire can reach it . . . and it is placed obtrusively enough that the coxswain won't forget to make use of it.

Have a great rigger trick that solves a seemingly unsolvable hassle at your boathouse? Share your tips--and hacks--in the comments below.

Have a great rowing hack to suggest for future inclusion here? Send it to us!

If you enjoy and rely on row2k, we need your help to be able to keep doing all this. Though row2k sometimes looks like a big, outside-funded operation, it mainly runs on enthusiasm and grit. Help us keep it coming, thank you! Learn more.

Comments | Log in to comment |

There are no Comments yet

| |

- Bont Rowing

- Calm Waters Rowing

- Concept 2

- Craftsbury Sculling

- The Crew Classic

- CrewLAB

- Croker

- Durham Boat Co.

- Empacher

- Faster Masters

- Filippi

- Fluidesign

- h2row.net

- HUDSON

- Live2Row Studios

- Nielsen-Kellerman

- Oak Ridge RA

- Peinert Boat Works

- Pocock Racing Shells

- Race1 USA

- RowKraft

- Rubini Jewelers

- Vespoli USA

- WinTech Racing

- Bont Rowing

- Calm Waters Rowing

- Concept 2

- Craftsbury Sculling

- The Crew Classic

- CrewLAB

- Croker

- Durham Boat Co.

- Empacher

- Faster Masters

- Filippi

- Fluidesign

- h2row.net

- HUDSON

- Live2Row Studios

- Nielsen-Kellerman

- Oak Ridge RA

- Peinert Boat Works

- Pocock Racing Shells

- Race1 USA

- RowKraft

- Rubini Jewelers

- Vespoli USA

- WinTech Racing